Pulished on May. 21, 2023

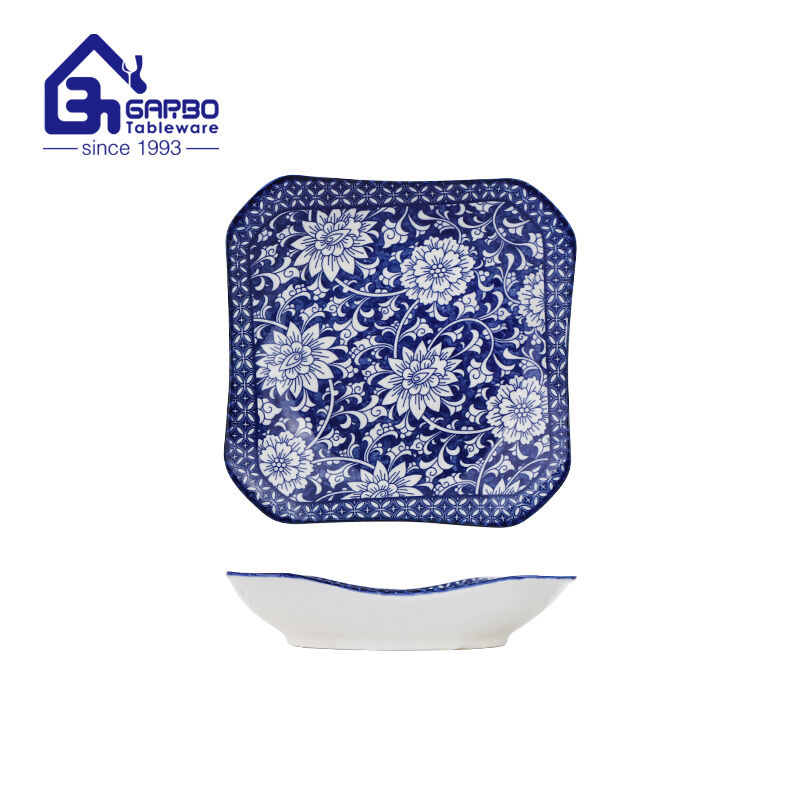

Porcelain tableware has always been cherished for its elegance and timeless beauty. One of the most captivating decorative techniques employed in porcelain manufacturing is underglazed printing. This article provides an in-depth introduction to the underglazed printing process for porcelain tableware. We will explore its history, materials, techniques, advantages, limitations, industry applications, and modern innovations. Join us on this journey as we unravel the artistry behind underglazed printing.

History

Underglazed printing has a rich historical legacy that dates back centuries. Its origins can be traced to ancient civilizations such as China and Persia. The process has evolved over time, adapting to various cultural influences and technological advancements. Today, underglazed printing stands as a testament to the skill and craftsmanship of porcelain artisans throughout history.

To create exquisite underglazed prints, artisans utilize specific materials and tools. High-quality porcelain, known for its translucency and durability, serves as the canvas for these intricate designs. Various pigments and colors are carefully chosen to achieve vibrant and long-lasting results. Brushes, sponges, and other specialized tools are employed to bring the designs to life.

Before the printing process begins, thorough preparation is essential. The porcelain surface must be meticulously cleaned and made ready for the underglaze application. Artisans trace the design onto the surface using transfer paper or create freehand sketches. Pigments are mixed with precision, ensuring the desired colors and shades are achieved.

Underglazed printing encompasses several techniques, each offering unique characteristics and possibilities. Hand painting allows for intricate details and customization, where skilled artisans paint directly onto the porcelain. Stencil printing involves using pre-cut stencils to apply underglaze, providing consistency in repetitive patterns. Transfer printing utilizes specially printed paper to transfer the design onto the porcelain surface, enabling mass production.

Firing plays a crucial role in underglazed printing, as it transforms the applied underglaze into a permanent decoration. The porcelain pieces are carefully loaded into kilns, which can be electric, gas, or wood-fired. Controlled temperature and duration ensure the underglaze fuses with the porcelain, resulting in a durable and captivating finish.

After the firing process, a layer of glaze is applied to the porcelain to enhance its appearance and protect the underglazed prints. This glaze adds depth, shine, and a smooth texture. Artisans pay meticulous attention to the final touches, ensuring all details are accentuated and the overall design is flawless.

Underglazed printing offers numerous advantages that contribute to its popularity in the porcelain industry. Firstly, underglazed prints exhibit exceptional durability, making them resistant to fading and wear. Secondly, the versatility of this printing process allows for intricate designs, personalized touches, and the incorporation of various artistic styles. Finally, underglazed prints possess an undeniable aesthetic appeal, captivating admirers with their beauty and sophistication.

While underglazed printing offers remarkable possibilities, it also presents certain limitations and challenges. Complex designs require meticulous precision, as any mistakes during the printing process can be difficult to rectify. Color variations may occur due to factors such as firing temperature and pigment composition, demanding the expertise of skilled artisans. Mastering the underglazed printing technique takes time, practice, and a keen eye for detail.

Underglazed printing finds its application in various industries beyond tableware. Its decorative charm extends to porcelain dinnerware, tea sets, vases, and figurines. The artistry of underglazed prints also makes them highly sought after by collectors and enthusiasts. The versatility and enduring appeal of underglazed printing ensure its continuous presence in the porcelain industry.

With advancements in technology, underglazed printing has embraced modern innovations. Digital underglaze printing allows for precise reproduction of intricate designs, opening up new possibilities for customization and personalization. Automation and mass production have made underglazed printed porcelain more accessible, catering to a wider range of consumers while maintaining the integrity of the craft.

To ensure the longevity of underglazed printed porcelain, proper maintenance and care are crucial. Cleaning guidelines must be followed to prevent damage to the prints and the porcelain itself. It is advisable to hand wash underglazed printed tableware and avoid harsh detergents or abrasive scrubbing. With proper care, underglazed prints can retain their beauty and charm for generations to come.

In recent years, sustainability and environmental awareness have become essential considerations for the porcelain industry. Underglazed printing can align with sustainable practices through responsible waste management, minimizing the use of harmful chemicals, and adopting energy-efficient firing techniques. The industry continues to explore ways to reduce its ecological footprint while preserving the artistry and tradition of underglazed printing.

Underglazed printing is a captivating art form that elevates porcelain tableware to new heights of beauty and sophistication. From its historical roots to modern innovations, this technique has enthralled admirers for centuries. The meticulous craftsmanship, versatility, and enduring appeal of underglazed prints make them a cherished addition to any table setting or decorative collection. The artistry behind underglazed printing stands as a testament to the human touch that adds soul and character to everyday objects.

1. Can underglazed printed porcelain be used in the microwave?Underglazed printed porcelain is generally microwave-safe, but it is advisable to check the ceramic dinnerware manufacturer's guidelines for specific products to ensure they are suitable for microwave use.

2. How long does the underglazed printing process take?The duration of the underglazed printing process depends on factors such as the complexity of the design, the number of pieces being printed, and the drying and firing times. It can range from several hours to a few days.

3. Can underglazed prints fade over time?Underglazed prints are known for their durability and resistance to fading. With proper care and maintenance, they can retain their vibrancy and beauty for many years.

4. Is underglazed printing suitable for dishwasher use?Underglazed printed porcelain is generally dishwasher-safe. However, to ensure the longevity of the prints, it is recommended to use a gentle dishwasher cycle or hand wash whenever possible.

5. Can I create my own designs for underglazed printing?Yes, underglazed printing offers opportunities for personal creativity. You can create your own designs or work with skilled artisans to bring your ideas to life on porcelain tableware.