Pulished on Jul. 28, 2023

Do you curious about how a new porcelain cup is produced from just an idea?

As a professional supplier of the ceramic tableware, we will introduce the process for creating a new ceramic mug or cup to you.

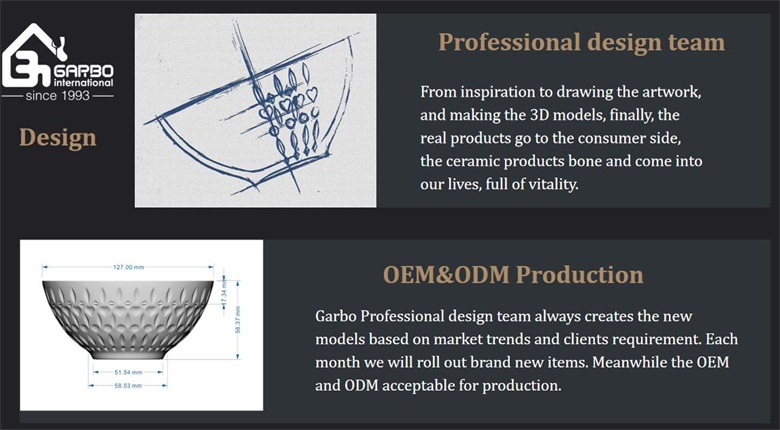

Begin by brainstorming and sketching ideas for the ceramic mug. Take the factors such as shape, size, and handle design into your consideration.

Only have a good idea for the ceramic cup, if you don't put it into effect, it is just an idea in your brain forever.

Ceramic mug manufacturer has a professional design team to help you to make your ideas come true. Our design team will create a detailed and professional design drawing of the porcelain cup via computer-aided design (CAD) software or 3D software.

This step will involve specifying exact dimensions, thickness, and other intricate details for the porcelain cups. Our design team is familiar with and professional in the porcelain cup production craft.

We can help you to modify the data in your ideas to fit the physical craft well, such as the wall thickness, post-processing color, and shape adjustment.

Decide on the type of porcelain to be used, the price of these new ceramic cups also depends on the raw material you choose.Please, do more surveys on the market before the decision. If you want to create a new design of ceramic cups to hit the existing market, you are supposed to pick the design according to your functional requirements and sell it in the market. Of course, the different raw material of the ceramic has a different texture to the new ceramic cups. For example, the stoneware cup usually can show the

nature texture of the stoneware itself, and it is suitable for adding the glazed color or hand painting band.

When it comes to new bone china raw material cup, which has a lighter weight, high-end quality, and luxury style and it is great as a gift to friend and family. But it has a higher cost than the stoneware cups.

Garbo ceramic mug manufacturer has rich experience in raw material choosing, if you have questions or problems in selecting the raw material, you can just come to us for help.

After using the raw material, the next step is to produce the physical prototype. Usually, we will use 3D printing or open a handmade mold based on the designed data to get samples.

It takes around only 2 days to get 3D samples and around 2 weeks to get a handmade mold sample. It can help us to test and understand the design for ergonomics, functionality, and aesthetics well.

After getting the samples in hand, we will make some adjustments based on the actual case and production craft. The testing sample can help us to save time and modify the unfit parts.

It can help us to avoid production problems in the coming manufacture and make the samples more perfect.

When it comes to mass production, we will open new molds for the ceramic mug's body, handle, and any other components according to the design drawing.

It takes around 2 weeks or more times to create the tooling mold.

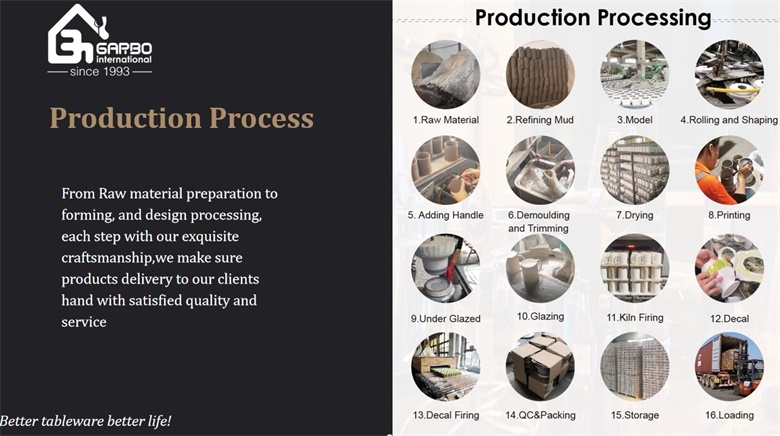

Once the designed steps are finished and the sample confirms, we will prepare the raw material for the porcelain cups, such as the packing raw material, porcelain raw material, the decal paper,

and the painting raw material as listed. We will check on the standard production line and arrange the experienced workers to get the ceramic cups manufactured as planned.

The actual manufacturing process for the porcelain begins. The new design porcelain cup is carefully produced in our standard production lines, including the molding, rolling and shaping, adding a handle,

molding and trimming, drying, printing, under glazing, glazing, kiln firing, adding the decal decoration, and decal firing.

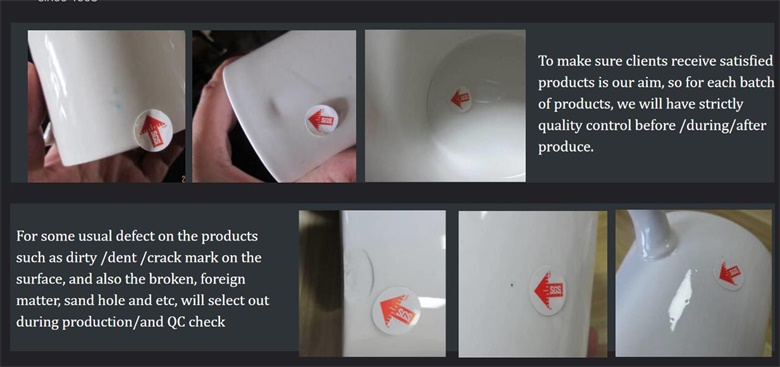

Garbo tableware in-house strict quality control measures are implemented to ensure each mug meets the desired standards on the incoming raw material, during production and production finished.

The defective porcelain cup will be removed from the production line and won't be packed and sent to the clients.

The finished unique ceramic mugs are packed well as your requirement to avoid any crush or damage during transportation before reaching the destination.

These new ceramic cups will reach the final customer via the importer, wholesaler, supermarket, or online shops. You are supposed to make the advertisement or promotion on the new unique ceramic mugs to help sell them well.

Garbo tableware is always here during the whole process to produce a new ceramic mug with you. If you have any questions about it, pls feel free to contact us.